Six sigma in project management - a quick guide

Six Sigma is a method that uses statistics to measure how well a process performs. It aims for near perfection, with a defect rate close to zero. Developed by Motorola in the 1980s, Six Sigma is now used by many companies, like General Electric, Toyota, and Amazon, across various industries. It helps them improve customer satisfaction, reduce costs, and boost profits.

What is Six Sigma?

Six Sigma isn't just a fancy term, it's a method for businesses to significantly improve their processes. By focusing on reducing defects and variations, Six Sigma helps achieve near-perfect quality. Imagine a process with only 3.4 mistakes per million opportunities!

This is achieved through a structured approach called DMAIC. It stands for Define, Measure, Analyse, Improve, and Control. Each step helps identify and eliminate the root causes of inconsistencies in a process, ultimately leading to improvements.

The term "Six Sigma" itself has a statistical origin. "Sigma" (σ) is a symbol used to measure how much a process deviates from its ideal state. In a perfect world (represented by a bell curve), six sigmas (three above and three below the average) signifies an extremely low defect rate.

What is Lean Six Sigma?

Think of Lean Six Sigma as a powerful one-two punch for improving your business processes. It combines the strengths of two methodologies - Lean and Six Sigma.

- Lean focuses on eliminating waste. It identifies activities that don't add value and trims them away. This streamlines processes, reduces defects, and improves quality, all while using fewer resources. Basically, it's about doing more with less.

- Six Sigma, on the other hand, is a data-driven approach that minimises variations and defects. It uses a structured method (DMAIC) to define, measure, analyse, improve, and control processes, ensuring consistent and predictable results.

By combining these two techniques, Lean Six Sigma offers a comprehensive approach to process improvement. It can be applied across various industries, from manufacturing to healthcare, to boost efficiency, cut costs, and ultimately, make your customers happy.

The 5 pillars of Six Sigma

Six Sigma isn't just about tools and techniques, it's built on a strong foundation of principles. These five core principles guide the entire process:

1. Customer focus

Everything starts with the customer. Six Sigma emphasises understanding customer needs and expectations. This becomes the benchmark for defining quality in your processes.

2. Data-driven decisions

Forget hunches and guesswork. Six Sigma relies on data to identify problems and measure improvements. By mapping the value stream, you pinpoint areas of waste and inefficiency. Data then helps you target the specific problem areas for transformation.

3. Eliminate waste

Not all process steps are created equal. Six Sigma identifies and removes activities that don't add value for the customer. This streamlining reduces defects and improves overall efficiency.

4. Teamwork makes the dream work

Six Sigma isn't a one-man show. It requires collaboration across all levels. By involving stakeholders and leveraging their diverse expertise, you create a strong team environment for problem-solving.

5. Embrace change

Six Sigma is about continuous improvement. When inefficient processes are removed, it can necessitate changes in work practices and employee mindsets. This principle encourages a culture of flexibility and adaptability to ensure long-term success.

Six Sigma's tool belt - DMAIC and DMADV

Six Sigma offers two main methodologies to tackle process improvement - DMAIC and DMADV. Both involve a series of steps but cater to different scenarios.

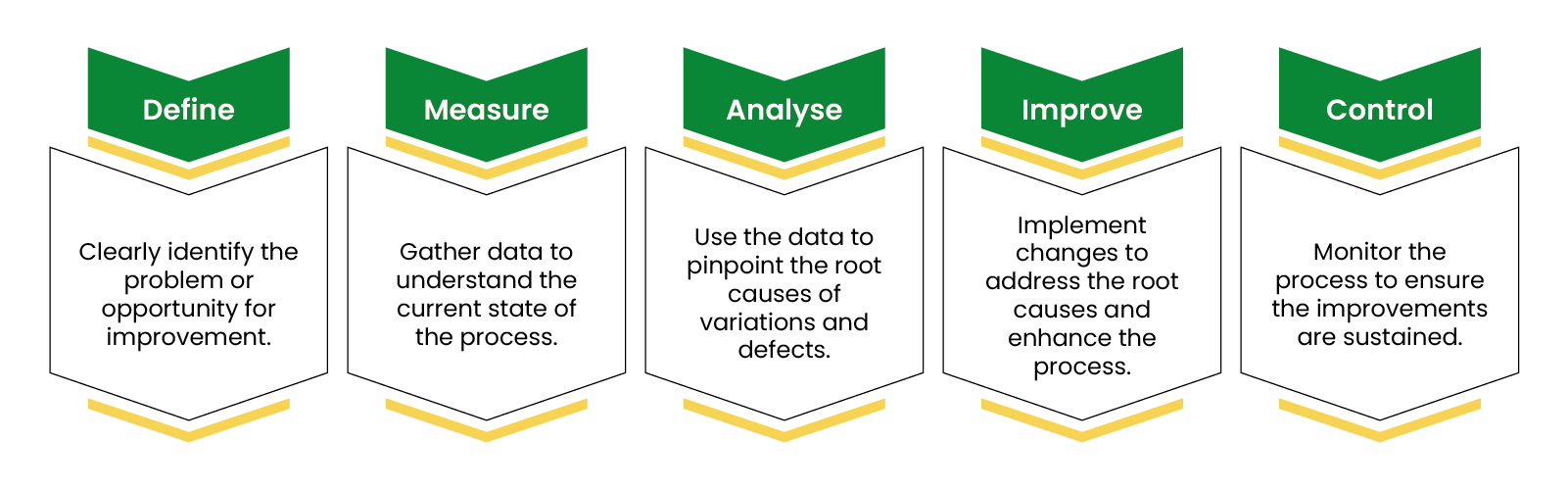

DMAIC - The doctor for existing processes

Imagine DMAIC as a doctor for your existing processes. It's a data-driven, five-step approach used to diagnose and improve current products or services, ultimately leading to better customer satisfaction. Let's break down the steps:

- Define - Clearly identify the problem or opportunity for improvement.

- Measure - Gather data to understand the current state of the process.

- Analyse - Use the data to pinpoint the root causes of variations and defects.

- Improve - Implement changes to address the root causes and enhance the process.

- Control - Monitor the process to ensure the improvements are sustained.

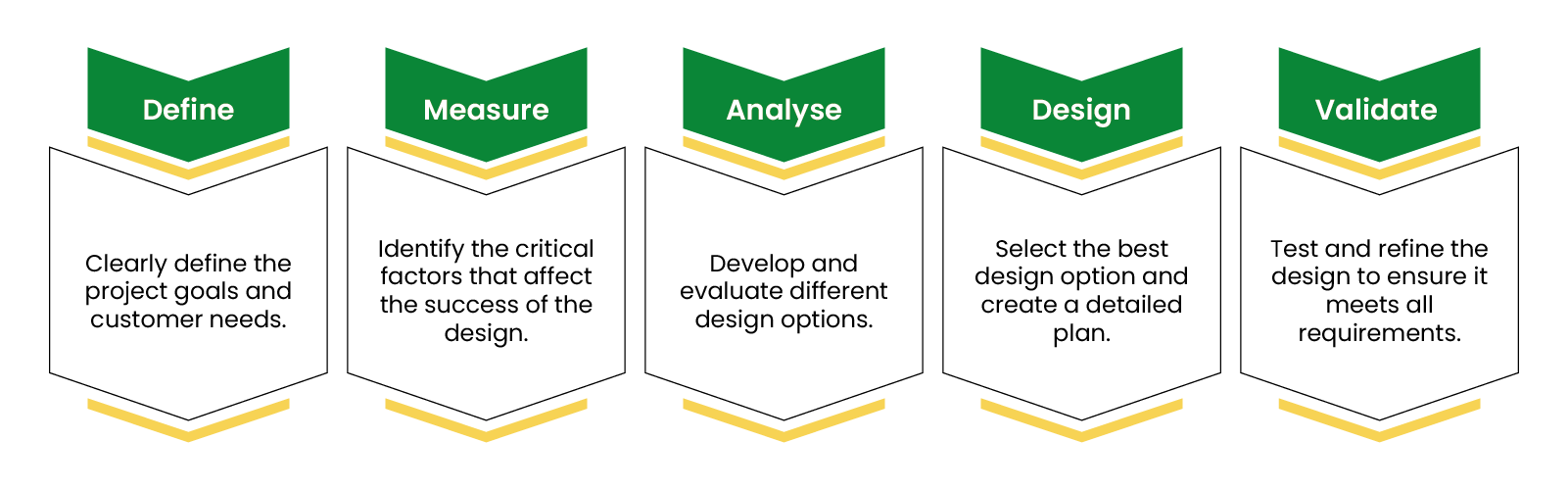

DMADV - Designing for success from scratch

If you're building something entirely new, DMADV is your guide. This five-step methodology is part of Design for Six Sigma (DFSS) and focuses on creating processes that are efficient and minimise defects right from the start. Here's how it works:

- Define - Clearly define the project goals and customer needs.

- Measure - Identify the critical factors that affect the success of the design.

- Analyse - Develop and evaluate different design options.

- Design - Select the best design option and create a detailed plan.

- Validate - Test and refine the design to ensure it meets all requirements.

By understanding the strengths of DMAIC and DMADV, you can choose the right approach to optimise your business processes, whether you're revamping existing ones or building entirely new systems.

The DMAIC roadmap of business transformation

While Six Sigma offers various tools, DMAIC is the core methodology used by practitioners. It's a data-driven, five-step approach that guides business transformation. Here's a breakdown of each phase:

- Define - This customer-centric phase sets the stage. You clearly define the problem or opportunity for improvement, ensuring it aligns with customer needs.

- Measure - Here, data takes centre stage. You identify the key metrics relevant to the project and choose the right tools to measure them. This data paints a clear picture of the current process performance.

- Analyse - Time to delve into the "why" behind the problem. This phase involves analysing the process to identify the root causes of variations and defects.

- Improve - Armed with insights from the analysis, you develop and implement solutions to address the root causes. This phase focuses on how to improve the process implementation for better results.

- Control - Sustainability is key. The final phase ensures the implemented improvements are effective and long-lasting. You monitor the process to confirm it meets the performance objectives and adjust if needed.

By following the DMAIC roadmap, Six Sigma empowers businesses to continuously improve their processes, leading to increased efficiency, reduced costs, and ultimately, a higher level of customer satisfaction.

Is Six Sigma a perfect fit for your project?

Six Sigma can be a powerful tool, but it's not a one-size-fits-all solution. Before diving in, consider these factors to see if it aligns with your project needs:

- Strengths and limitations - Six Sigma excels at incrementally improving existing processes in large-scale manufacturing or service delivery. It might not be the best choice for projects seeking radical innovation or those with limited resources.

- Project management - Six Sigma focuses on process improvement, not necessarily project management itself. Consider combining it with a dedicated project management methodology for optimal results.

Training and investment - Implementing Six Sigma company-wide requires extensive training for all team members. This investment in time and resources needs to be weighed against the expected benefits.

Here's how to decide:

- Evaluate different methodologies - Compare Six Sigma to other approaches. Consider factors like project type, budget, and desired outcomes.

- Focus on existing processes - If your project aims to refine established processes for efficiency and quality gains, Six Sigma can be a great fit.

Remember - Six Sigma is a powerful tool, but it's most effective when implemented strategically.

To explore Six Sigma training options, consider our Six Sigma courses for enhanced results:

When Six Sigma shines brightest

Six Sigma is a powerful tool, but like any tool, it works best in certain situations. Here's how to know if it's the right fit for your project.

Is it an operational project?

Six Sigma expert Bernardo Tirado emphasises its effectiveness for operational initiatives. These are projects focused on improving existing processes, often through technology or centralisation. Think of it as streamlining how things are already done.

Beyond operations

While operations are a sweet spot, Six Sigma can be valuable in other scenarios too:

- Waste reduction - Identify and eliminate wasted time, materials, or resources in your current processes.

- Defect and variation reduction - Minimise errors and inconsistencies in your products or services.

- Problem-solving - Use data analysis to pinpoint the root causes of process issues.

- Data-driven decisions - Leverage data to boost efficiency and productivity.

- Improved satisfaction - Enhance customer and employee satisfaction through process improvements.

- Process design/Redesign - Six Sigma can guide the design of entirely new processes or the revamping of ineffective ones.

By considering these factors, you can make an informed decision about whether Six Sigma is the right project management methodology for your needs.

Six Sigma - A recipe for business success

Change can be daunting, but Six Sigma's benefits extend far beyond project management, impacting your entire business in positive ways:

- Data-driven decisions - Six Sigma empowers you with data to make informed choices. By analysing data, you can identify the best solutions and optimise your performance for success.

- Stronger teams - Six Sigma fosters a collaborative spirit. Teams see problems as opportunities for improvement, working together towards a common goal of uncovering the truth behind process inefficiencies.

- Happier customers - Reduced defects and variations translate to a better customer experience. By measuring and analysing your processes, you can identify areas for improvement, leading to happier and more satisfied customers.

- Cost reduction - Six Sigma takes aim at waste and inefficiencies. Through structured teams, rigorous process reviews, and a data-driven approach, Six Sigma helps you cut unnecessary costs.

- Enhanced productivity - Improved team structure, planning, data analysis, and overall business strategy contribute to a more efficient organisation. This translates to better time management and allows you to focus on what truly matters.

In essence, Six Sigma equips your business with the tools and strategies to not only survive but thrive in today's competitive landscape.

Six Sigma's toolbox

Six Sigma goes beyond just a methodology, it equips you with a powerful toolbox of techniques. This arsenal combines statistical analysis, proven practices, and data-driven tools to achieve your desired outcome. Here are some key techniques used in Six Sigma:

- Brainstorming - Get creative! Brainstorming sessions encourage teams to freely generate ideas and explore different approaches to tackle problems.

- Root cause analysis (5 Whys) - Don't settle for surface-level issues. The 5 Whys technique helps you delve deeper by asking "why" repeatedly, ultimately uncovering the root cause of a problem.

- Voice of the customer (VOC) - Put your customer at the centre. VOC techniques capture customer needs and expectations, ensuring your processes deliver what truly matters.

- 5S system - Streamline your workspace! The 5S system (Sort, Set in Order, Shine, Standardise, Sustain) helps eliminate waste and bottlenecks by optimising the use of tools, equipment, and resources.

- Kaizen (Continuous Improvement) - Embrace the journey! Kaizen is a philosophy of continuous improvement. It encourages ongoing monitoring and identification of opportunities to refine processes, creating a constant cycle of betterment.

- Benchmarking - Learn from the best! Benchmarking involves comparing your processes and performance metrics against industry leaders. This provides valuable insights and helps identify areas for improvement.

- Poka-Yoke (Mistake-Proofing) - Prevent errors before they happen! Poka-yoke techniques aim to design processes that prevent human error and ensure quality by making mistakes virtually impossible.

- Value stream mapping - See the big picture! Value stream mapping visually charts the flow of materials and information in your process. It helps identify areas of waste and guides the design of future, more efficient workflows.

By mastering these techniques, Six Sigma empowers your team to identify and eliminate inefficiencies, leading to a more optimised and successful business.

Six Sigma's toolbox

Six Sigma goes beyond just a methodology, it equips you with a powerful toolbox of techniques. This arsenal combines statistical analysis, proven practices, and data-driven tools to achieve your desired outcome. Here are some key techniques used in Six Sigma:

- Brainstorming - Get creative! Brainstorming sessions encourage teams to freely generate ideas and explore different approaches to tackle problems.

- Root cause analysis (5 Whys) - Don't settle for surface-level issues. The 5 Whys technique helps you delve deeper by asking "why" repeatedly, ultimately uncovering the root cause of a problem.

- Voice of the customer (VOC) - Put your customer at the centre. VOC techniques capture customer needs and expectations, ensuring your processes deliver what truly matters.

- 5S system - Streamline your workspace! The 5S system (Sort, Set in Order, Shine, Standardise, Sustain) helps eliminate waste and bottlenecks by optimising the use of tools, equipment, and resources.

- Kaizen (Continuous Improvement) - Embrace the journey! Kaizen is a philosophy of continuous improvement. It encourages ongoing monitoring and identification of opportunities to refine processes, creating a constant cycle of betterment.

- Benchmarking - Learn from the best! Benchmarking involves comparing your processes and performance metrics against industry leaders. This provides valuable insights and helps identify areas for improvement.

- Poka-Yoke (Mistake-Proofing) - Prevent errors before they happen! Poka-yoke techniques aim to design processes that prevent human error and ensure quality by making mistakes virtually impossible.

- Value stream mapping - See the big picture! Value stream mapping visually charts the flow of materials and information in your process. It helps identify areas of waste and guides the design of future, more efficient workflows.

By mastering these techniques, Six Sigma empowers your team to identify and eliminate inefficiencies, leading to a more optimised and successful business.

Six Sigma's tools for data-driven improvement

Six Sigma goes beyond brainstorming and process mapping. It utilises a powerful set of statistical tools to analyse data and identify areas for improvement. Here are some key statistical tools used in Six Sigma:

- Cause and Effect Analysis (Ishikawa Diagram)

- Flowchart

- Pareto Chart (80/20 Rule)

- Histogram

- Check Sheet

- Scatter Plot

- Control Chart

By leveraging these statistical tools, Six Sigma empowers you to make data-driven decisions and optimise your processes for greater efficiency and effectiveness.

Six Sigma belts

Six Sigma offers various training levels tailored to specific requirements, educational criteria, job standards, and eligibility:

White Belt - Provides a foundational understanding of Six Sigma history, concepts, and methodology.

Yellow Belt - Offers an overview of Six Sigma theory, processes, and the DMAIC methodology.

Visit: Lean Six Sigma Yellow Belt

Green Belt - Introduces tools and methods for problem-solving and DMAIC implementation.

Visit: Lean Six Sigma Green Belt

Black Belt - Offers thorough training in methodologies and tools for business transformation.

Visit: Lean Six Sigma Black Belt

Master Black Belt - Empowers leaders for long-term business transformation with Six Sigma tools.

Six Sigma - A path to rewarding careers

Six Sigma's widespread adoption across industries like manufacturing, healthcare, finance, and retail translates to a diverse range of career opportunities. And the good news? These careers come with attractive salary prospects.

Team Leader - £31,000 (Approx. yearly)

Quality Manager - £46,000 (Approx. yearly)

Operations Manager - £48,000 (Approx. yearly)

Lean Six Sigma Consultant - £48,000 (Approx. yearly)

Lean Six Sigma Project Manager - £48,000 (Approx. yearly)

Lean Six Sigma Master Black Belt - £48,000 (Approx. yearly)

Process Improvement Manager - £51,000 (Approx. yearly)

Lean Six Sigma Black Belt - £52,000 (Approx. yearly)

Remember, Six Sigma certification can significantly enhance your earning potential and job prospects. Consider pursuing a Six Sigma certification to unlock a world of exciting career opportunities with attractive salaries.

Enrol in Six Sigma courses offered by Study365

Explore Study365's Six Sigma courses to enhance your career prospects and increase earning potential, whether you're a recent graduate, engineer, or MBA professional. Start with a Yellow Belt and progress to Master Black Belt to raise your salary. As a newcomer, enrol in Study365's Six Sigma programmes to grasp fundamental principles and advance through higher certificate levels as you gain practical experience. Visit the link below to begin your journey today: Click Here

Frequently asked questions

Register for free to receive relevant updates on courses and news from Study365.

Create an account to receive our newsletter, course recommendations and promotions.Related Products

>Leave a Message

Leave a Message

YOUR EMAIL ADDRESS WILL NOT BE PUBLISHED. REQUIRED FIELDS ARE MARKED.